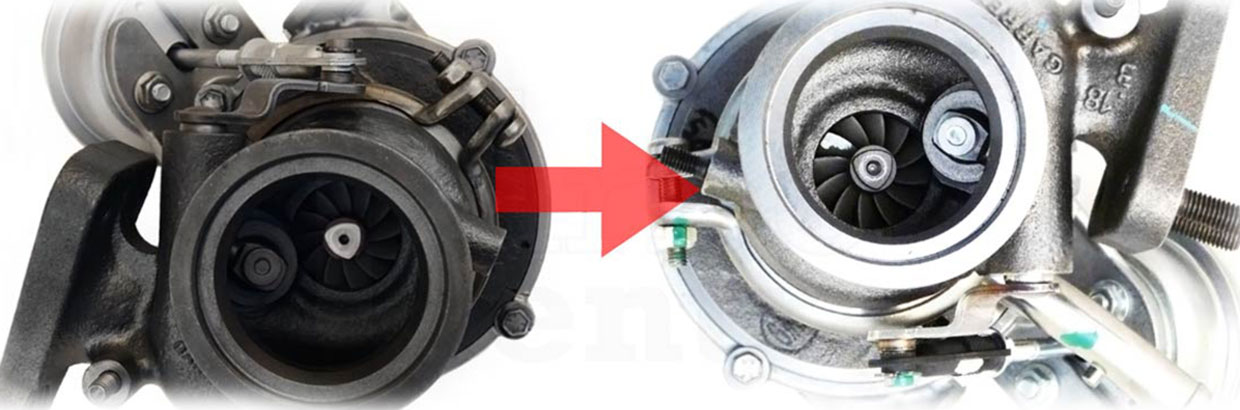

Replacement of a faulty turbo with a new or fully reconditioned turbocharger is a common practice in the turbochargers repair. Due to the request of the customer, instead of repairing the turbocharger, we make a replacement for it. Possessing all the technical base in our service center, experienced and skilled specialists will replace any turbochargers of all known cars brands.

Some enthusiasts replace the turbocharger in order to squeeze more power out of the car's engine. Not an exception is the cases when it is possible to install more powerful turbo on the engine, giving the car a greater speed of acceleration and increase its power. Such manipulations require extensive knowledge and experience, because you need to consider the type of turbocharger and its design features.

When replacing the turbocharger, as well as during the repair, it is necessary to comply with all installation rules and take all the features of the product into account. The most important point when replacing a turbo is to eliminate the cause of its malfunction, in order to avoid a repetition of the situation of the turbocharger getting out of order. It is equally important when replacing all engine oil, oil and air filters. Use only high-quality, type-appropriate, clean oil. Avoid getting dust, dirt, or any foreign objects into the turbocharger housing, into the nozzles and into the open engine channels. When installing the turbocharger, use only high-quality gaskets and strongly avoid the use of various sealants, compounds or other special means. It is the use of sealant that often causes a breakdown of the turbo. Sealants do not withstand high temperatures and in aggressive environments can react chemically with exhaust gases or oil. Fusing or crumbling into small particles, the sealant is sucked into the turbine housing, which causes irreparable damage to the impellers, rotor and other parts of the turbocharger. The neglect of the use of gaskets also leads to a depressurization of the turbo system, which leads to malfunctions in the engine and turbocharger operation.