The expediency of replacing the turbocharger with a new one often challenges the possibility of carrying out a minor or major turbocharger overhaul. Full reconditioning or minor repairs of the turbocharger in most cases will save money when repairing the car.

From own experience, experts know that a completely renovated turbocharger will serve no worse than a new one. The experience of observation showed that the difference in the service life between the new and the reconditioned turbocharger is insignificant or completely absent. In addition, it is already difficult to buy a lot of turbos and sometimes it is simply impossible to find them because of the removal of those from production.

Turbocharger Reconditioning - Turbo Rebuild Specialists

Our company has a network of equipped, modern repair shops that produce high-quality, professional repair of faulty turbochargers of all leading brands of cars. TurboCentras repairs and rebuilds faulty turbos of world brands, such as BorgWarner Turbo Systems (3K, KKK, Schwitzer), Garrett by Honeywell, Mitsubishi, Toyota and other less well-known manufacturers. Based on long experience of work and our strict quality policy, we provide only high-quality services for repair and reconditioning of turbochargers. Professional repairs of turbochargers are carried out by qualified, specially trained personnel using the most modern and reliable equipment. TurboCentras specialists will advise you on the repair and operation of the turbocharger, help determine the causes of the turbocharger malfunction, conduct a full diagnosis and evaluate all the characteristics of the turbocharger and its parts. Thanks to first-class modern equipment our specialists will cope with any task of restoring your turbocharger and eliminate turbo malfunctions of any complexity.

For all performed works on repair of turbochargers, our company provides a long-term guarantee with compliance with our quality policy.

Fast, high-quality and inexpensive repair of turbochargers is the sphere of activity of professionals with a wide experience of work, which is the company of TurboCentras.

The causes of turbocharger malfunctions

Why did the turbocharger break? ...

It is extremely important to establish the reason for the failure of the turbocharger before replacing it!

If the original cause of the failure of the turbocharger is not eliminated, all funds spent for repair or purchase of a new turbo will be wasted.

The turbocharger will break again!

It is established that the most common cause of turbo failure is an external factor, that means, the very cause of failure is not in the turbocharger, but in an external impact on it. By itself, the turbocharger does not have parts that are subject to excessive wear, working in modes that are provided by the manufacturer. The service life of the turbocharger is equated to the life of the engine. Manufacturers of turbochargers exclude the presence of defects in their products. It’s quite a reasonable exception, because in the production of modern turbochargers are used automated high-tech lines. The whole process of production passes a strict, automated control. Though, talking about the operation of the turbocharger, the situation is somewhat different and in time, in practice, we get a problem. A frequent case is when a turbo breaks down much earlier than it is supposed to serve. Not an exception are the cases when a new, recently installed turbocharger for some reason fails, before the vehicle can pass a hundred meters, immediately after the repair shop.

Old contaminated engine oil and aggressive environment

Oil from the engine goes to the turbocharger to lubricate the rotating parts of the turbocharger. Contaminated with foreign particles, the oil adversely affects the turbocharger, greatly deteriorating its moving parts, scratching and damaging its bushings and bearings. Large abrasive particles leave deep scratches in the form of grooves on the sleeves and bearings of the turbocharger. Such a typical wear of the turbocharger parts is most often associated with an unusable oil filter of the engine. Also, the cause of dirt in the engine oil may be inaccurate repair of the engine, opening the engine covers in adverse conditions. A significant excess of the engine oil life contributes to the formation of fine abrasive particles in the lubricant, the oil loses its lubricating properties, which leads to a strong wear of the shaft, gradually eroding its surface, a strong backlash of the turbocharger rotor appears. A poor-quality or unsuitable oil, the presence of foreign additives in the oil lead to chemical contamination of the engine oil, which contributes to intensive wear of the sliding parts of the turbocharger.

Overheating at the extreme operating conditions of the turbo

The cause of heavy wear on the rotating parts of the turbine can be overheating caused by a malfunction of the car's cooling system, improper operation of the gas distribution system, an inapplicable type of fuel. Also, a malfunction of turbo control system, a faulty air pressure sensor leads to foreign formations on the shaft and wheel, which contributes to their overheating. When overheated, violation of the temperature characteristics of the turbocharger leads to deformation of the turbine parts, the formation of cracks on the nozzles of the shaft. Inapplicable parameters of the control systems lead to out-of-range rotor speeds of the turbocharger, forming cracks on the blades, subsequently destroying the entire rotor. The lack of engine oil in the turbocharger leads to overheating and destruction of its parts. Deficiency of lubrication can be associated with the lack of such or poor-quality gaskets, which become an obstacle to the supply of oil to the moving, rotating parts of the turbocharger.

Damage turbo by foreign particles

Having entered into the turbocharger, solid foreign objects will inflict irreparable damage to its parts. As a result of inaccurate repair or installation, an external washer, nut, plastic, trapped in the turbocharger, will damage the turbocharger wheel or the entire turbocharger shaft. Even a small piece of soft paper, cardboard, wood will cause a complete imbalance of the turbocharger rotor, subsequently leading to complete destruction of the bushes and bearings. Damage of blades with foreign objects in turbos with variable geometry (VNT, VGT, VG) leads to the failure of the turbocharger geometry control system, which can lead to overheating or the assignment of incorrect turbocharger operation parameters. Sand or dust penetrated into the air channels of turbo, in a short time deform the turbocharger wheel blades and quickly wear out the remaining parts of the turbocharger. Inaccurate installation, poor quality air filter, leaky duct connection can be a serious cause of failure of the newly installed turbocharger.

The main signs of a turbocharger malfunction

Only by a specialist in the service center with knowledge and equipment can identify the fault and make a conclusion. Further, the initial, basic features on which it is possible to make an assumption about turbocharger malfunction are described.

Turbocharger is very noisy when working

Strong noise can be caused by rubbing the rotor against the turbocharger housing. Also, the noise can be heard with a friction causing deformation of the housing or deformation of other parts of the turbo. When rubbing, the overheating and destruction of the blades are inevitable, followed by the inevitable failure of the turbocharger.

When the turbocharger is operating, a whistle is heard, or a noise similar to a whistle

Usually the whistling is due to the non-tightness of the turbo system. A leakage of air may occur at the place where the motor is connected to the compressor. The hole in the inter-cooler or the connection points with it can also cause an audible whistle.

There are stains of oil in the joints of the air pipes

Clogging an oil pipe, inter-cooler or airline usually causes oil leakage through air ducts. Motor oil, being under pressure, simply has nowhere to go. Also, possibly a low-quality oil or oil with additives was converted into coke during burn-out, thus forming strong clogs inside the turbocharging system.

Bad acceleration of the car, the car's power is lost

There may be a malfunction in the turbocharger control system. The turbocharger does not supply enough air to the engine. In turbos with variable geometry (VNT, VGT, VG) one of the reasons for poor acceleration and power drop may be the jammed nozzle ring jammed due to the deposit. The carbon is in turn formed from a poor-quality oil, fuel, due to a faulty air injection system.

Exhaust gases of black color

The fault can be in the turbocharger control system. The black color of exhausts can occur when the fuel mixture is too rich in air. The fault may be not the tightness of the air injection system. The hole in the inter-cooler or the nipples, that connect it to the rest of the turbochargers, can let the air through.

Exhaust gases of blue color, disappearing with time

Blue smoke is caused by burned oil in the cylinders. With heavy wear of parts in the turbocharger, it is possible to leak oil into the cylinders and combustion chamber of the engine. When the engine warms up, the details of the mute are deformed, becoming in place and the oil ceases to flow and the blue smoke disappears.

Full or standard turbocharger repair

The cost of repairing the turbo determines the complexity of the failure and the cost of parts replaced during repair. The approximate cost of repairs is determined after the diagnosis of the turbocharger. Repair of the turbocharger is divided into two types, to be more precisely, into two categories of repair.

Standard turbocharger repair

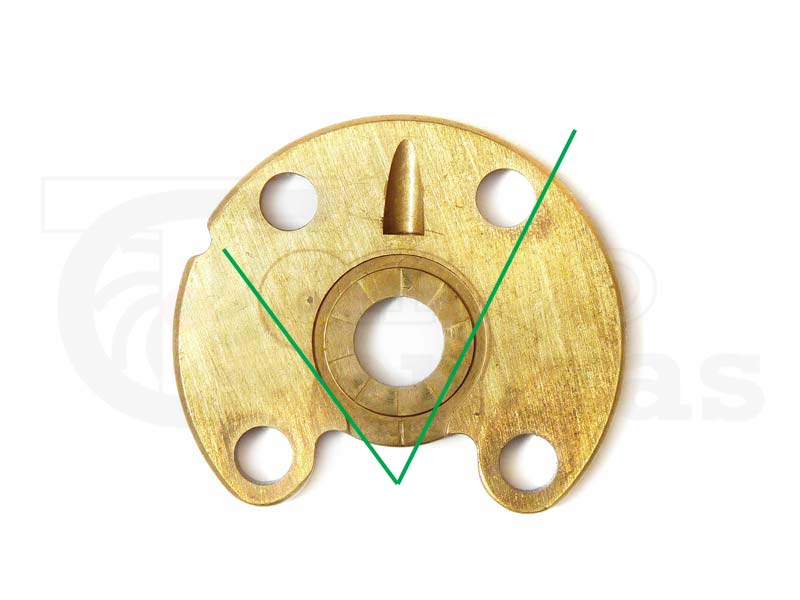

The first category is standard repair of the turbocharger. The standard repair of the turbo is performed with the wear of the bushings, gaskets, rings and other small parts. The repair uses a new repair kit (repair kit) of the turbocharger, all parts are replaced from a suitable repair kit for the given turbo. The shaft and wheel, while in good condition, cannot be replaced.

The course of work, the actions performed with the standard repair of the turbocharger:

- The turbocharger housing is removed;

- All the mechanisms of the turbocharger are sorted out;

- Details of the turbocharger are placed in the washing device and washed with special chemicals. The cleaning chamber of the cleaning device removes dirt in the form of carbon deposits, rust, soot, coke, burnt oil and other contaminants that are the product of the internal combustion engine;

- Surfaces of the turbocharger housing in special equipment are subjected to cold abrasive treatment, using an abrasive powder;

- The housing and turbocharger parts are re-washed in a chemical solution;

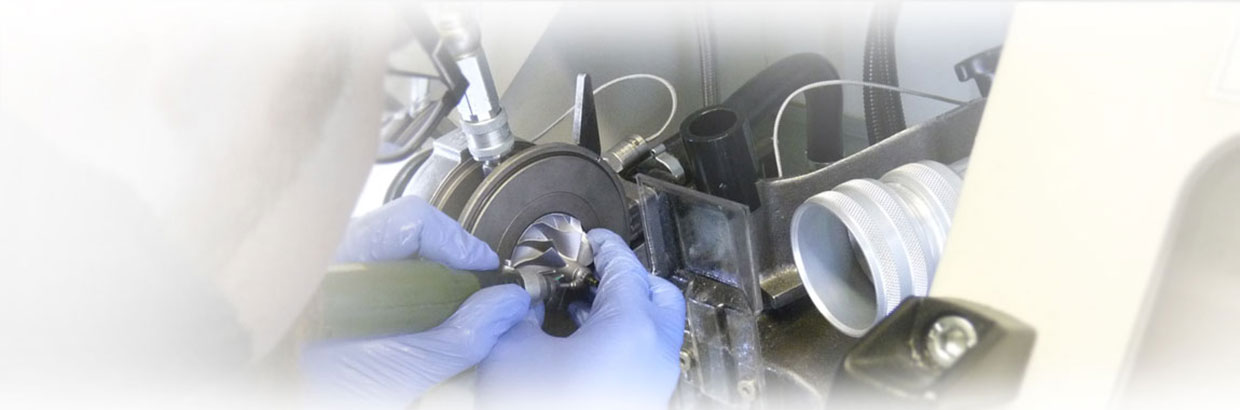

- With special equipment help balancing the rotor (turbocharger shaft);

- The core (turbo cartridge) of the turbocharger is assembled into which high-quality parts of the new repair kit (bushings, rings, etc.) are assembled;

- Balancing of the turbocharger cartridge is performed on special balancing equipment;

- Complete assembly of the turbocharger;

- The work on repair of turbo completes the final check of its operation, the final tests and measurements of characteristics are carried out.

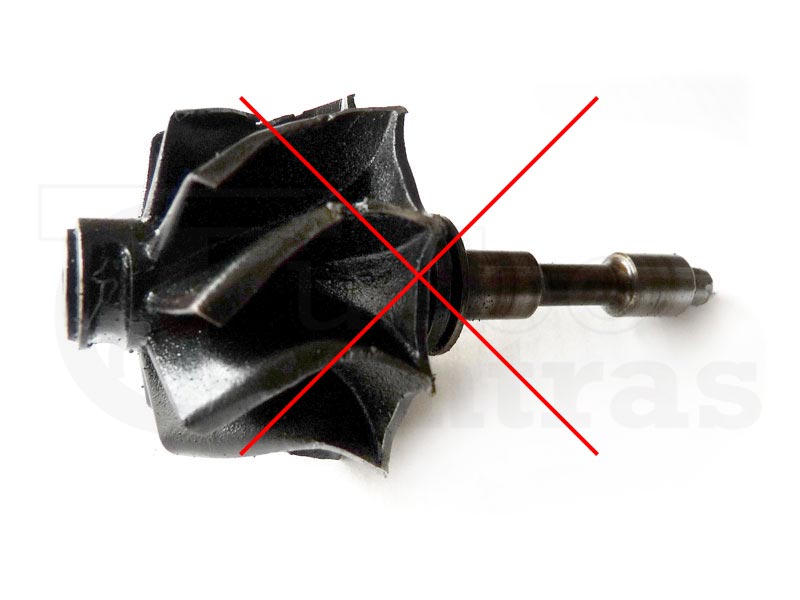

Full turbocharger repair

The second category of repair is a complete rebuilding of the turbocharger. Full repair of the turbo is performed with a strong deterioration of the rotor (shaft and wheel). The work on the complete repair of the turbocharger is similar to the standard repair, except for the replacement of a faulty rotor, worn shaft and wheel. Performing a complete repair of the turbo, it is possible to replace the whole cartridge (the core of the turbocharger) entirely or replace its individual parts.

Actions, work progress in case of complete repair of the turbocharger:

- The turbocharger housing is being disassembled;

- All turbocharger mechanisms are dismantled;

- Using special equipment with the help of chemicals, the parts are cleaned. The carbon deposits, rust, soot, coke and other contaminants typical of a turbocharger are removed;

- With cold abrasive treatment, the surface of the turbo housing is cleaned;

- In the cleaning chamber, the components of the turbocharger are re-cleaned with chemicals;

- The cartridge (core) of the turbocharger consists of a new, previously balanced shaft, bearing housing, sleeves, rings and other parts. As in the case of standard repairs, the assembly also uses a new turbocharger repair kit;

- The assembled cartridge is placed in special balancing equipment, where it is balanced with the parameters set for the current turbo;

- The turbocharger is fully assembled;

- Completion of the work on the full repair of the overall performance check of turbo, the performance of all tests on the suitability of the turbocharger for operation.

Diagnosis of turbocharger malfunction - the simplest ways

There are simple ways to identify a turbo malfunction without dismantling it from the engine. However, a complete diagnosis and conclusion on the status of the turbocharger can only be done at the service center by removing the turbo from the engine and conducting diagnostic tests on specialized stands. Complete diagnostics of the turbocharger should be performed by qualified personnel in the presence of proper equipment for repair and diagnostics of turbochargers.

Diagnosis of turbocharger on engine

The following describes of actions that allow to partially diagnose some malfunctions of the turbocharger without removing the turbocharger from the engine.

- The airlines are turned off from turbo. The branch pipes connecting the turbocharger with the air filter and the intercooler are removed. Disconnected air channels must be dry or slightly damp from oil fumes. If a significant amount of engine oil is observed in the air connections and their connection points, and the total oil consumption of the vehicle is greatly increased, the cause of the leak must be established precisely. The problem can be either in the turbocharger or in the engine;

- The shaft and wheel should be inspected. Blades of the wheel should not be worn or worn out, bent or otherwise deformed. The wheel must have regular, symmetrical shapes. If there are defects on the wheel, the turbocharger must be repaired or replaced;

- Try to set the turbocharger shaft (rotor) in motion along its axial direction. This can be done simply by hand, pulling the shaft (rotor), grasping the fingers of the shaft or wheel. The backlash in the axial direction should not exceed 0.05 mm and should not be felt fundamentally by the hand. If the movement of the turbocharger shaft in the axial direction exceeds the declared, the turbo needs to be repaired or changed;

- Stir the shaft in the radial direction of the axis. The movement of turbo shaft in the radial direction can be felt by hand. The gap in this direction should not exceed 1.00 mm. Pulling and turning the wheel, it should not touch the walls of the cold part of the turbocharger. If the wheel of turbo or its blades are in contact with the turbocharger housing, this turbocharger malfunction must be eliminated;

- Inspect of the turbocharger external parts. For a long time of operation of turbo, its body can crack or deform. This will take into account almost any turbocharger over time, regardless of the model, terms of use, manufacturer or brand of the car. Having discovered a crack, split, or other kind of critical deformation of the hull, repair is needed to immediately repair turbo or replace it.

Diagnostics of a turbocharger on test benches

The turbocharger removed from the engine passes a series of tests and tests using special equipment. Diagnostics is carried out by experienced specialists using high-tech, modern means.

The main test of a turbocharger under stationary conditions is to diagnose its core (turbo cartridge).

- It is necessary to disassemble the turbocharger and remove its cartridge (core);

- The turbocharger cartridge is placed in the balancing equipment, where a dynamic test passes, rotating the turbocharger shaft at speeds up to 200,000 rpm;

- Analyze the vibration spectrum of the turbo rotor when it rotates at different speeds. The test characteristics of rotational parameters and vibrations of the shaft are made;

- The cartridge is balanced by removing metal parts from the rotor causing excessive vibration. Balancing is carried out in strict accordance with the specified norms of the manufacturer of the turbocharger;

- If there is an electronic actuator at turbo, testing of its mechanical parts, checking the operability of electronics, the software is corrected. Pneumatic, vacuum actuators are also tested;

- All turbo parts are assembled back. The turbocharger is fully assembled.

Turbocharger service life - general recommendations

For normal operation of the turbocharger, it is recommended to carry out regular maintenance of the vehicle on a regular basis. Do you want the turbocharger to serve you long? Just keep up with a simple list of recommendations.

- Perform regular maintenance;

- Change the engine oil regularly;

- Fill in only quality oil;

- Regularly change the oil and air filters;

- Do not use unchecked additives for the engine;

- Follow the recommendations of the car manufacturer.

For quality repair of turbochargers, please contact the experts. For a long time, our company is engaged in repair and full recovery of turbocharger. We have gained a lot of experience in the field of turbo repair. The scope of the service market for repair of turbos for us is not limited to local activities. Many foreign partners prefer to trust the repair of turbochargers to our specialists. Our success in the repair of turbochargers is due, above all, to the high quality of our services. Qualitative repair of turbochargers is the beginning and continuation of our professional and beloved business. Without a doubt, we are always ready to assist in the repair of turbochargers, both to large partners and ordinary users who wish to repair the turbocharger.

@ TurboCentras